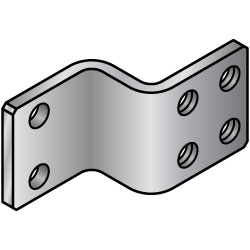

Sheet Metal Mounting Plate / Bracket -Z Bending Type- SWBCS (Part Numbers - CAD Download)

- Order quantities extended (D-JIT)

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- Catalog

- Technical Information

| Part Number | Material | Surface Treatment | |

| Type | Material Symbol | ||

| SWBCS | SP | EN 1.0330 Equiv. | - |

| SPB | Black Oxide | ||

| SPU | Trivalent Chromate (Clear) | ||

| SPK | Trivalent Chromate (Black) | ||

| AM | EN AW-5052 Equiv. | - | |

| AMW | Anodize (Clear) | ||

| AMB | Anodize (Black) | ||

| SUD | EN 1.4301 Equiv. (2B) | - | |

Specifications

| Part Number | - | A | - | B | - | T | - | H | - | J | - | X | - | Y | - | W | - | Hole Specification Code, Nominal Value | - | K | - | F | - | E | - | S | - | G | - | Hole Specification Code, Nominal Value | - | D | ||

| Type | - | Material Symbol | ||||||||||||||||||||||||||||||||

| SWBCS | - | SP | - | A80 | - | B40 | - | T3.2 | - | H30 | - | J40 | - | X20 | - | Y10 | - | W20 | - | N4 | - | F40 | - | E10 | - | S6 | - | G28 | - | MA3 | ||||

| Part Number | 1mm Increment | Selection | 1mm Increment | J | X | Y | W | Hole Specification | F | E | S | G | Hole Specification | ||||

| Type | Material Symbol | A | B | T | H | Code / Specify Method | Code / Specify Method | ||||||||||

| SWBCS | SP SPB SPU SPK AM AMW AMB SUD | 20 ~ 200 | 10 ~ 200 | EN 1.0330 Equiv. (EN 1.0320 Equiv. (hot coiled)) 1.6 2.3 3.2 4.5 6.0 | EN AW-5052 Equiv. 1.5 2.0 3.0 | EN 1.4301 Equiv. 1.5 2.0 3.0 4.0 | 10 ~ 100 | 0.1mm Increment | N (Bolt Hole) 0, 3, 4, 5, 6, 8, 10 Selection | 0.1mm Increment K≤Nx5 | NA (Bolt Hole) 0, 3, 4, 5, 6, 8, 10 Selection | ||||||

| M (Tapped Holes) 0, 3, 4, 5, 6, 8, 10 Selection | MA (Tapped Hole) 0, 3, 4, 5, 6, 8, 10 Selection | ||||||||||||||||

| When T≥3.0, A≥30 | |||||||||||||||||

| If the specified hole location is close to the edges, the hole may be deformed but will be machined as specified if within machining limits. | |||||||||||||||||

N, NA machining dimensions

| N, NA specified Value | 0 | 3 | 4 | 5 | 6 | 8 | 10 |

| Through Hole Dia. (d) | (No Hole) | 3.5 | 4.5 | 5.5 | 6.5 | 9 | 11 |

Alterations

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

Loading...

| Part Number | Minimum order quantity | Volume Discount | RoHS | Material | Surface Treatment | A (mm) | B (mm) | T (mm) | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 8 Days | 10 | EN AW-5052 Equiv. | Not Provided | 20 ~ 200 | 10 ~ 200 | 1.5 ~ 3 | ||

| 1 | 13 Days | 10 | EN AW-5052 Equiv. | Black Anodize | 20 ~ 200 | 10 ~ 200 | 1.5 ~ 3 | ||

| 1 | 13 Days | 10 | EN AW-5052 Equiv. | Clear Anodize | 20 ~ 200 | 10 ~ 200 | 1.5 ~ 3 | ||

| 1 | 7 Days | 10 | EN 1.0330 Equiv. (EN 1.0320 Equiv. (hot-rolled)) | Not Provided | 20 ~ 200 | 10 ~ 200 | 1.6 ~ 6 | ||

| 1 | 12 Days | 10 | EN 1.0330 Equiv. (EN 1.0320 Equiv. (hot-rolled)) | Black Oxide | 20 ~ 200 | 10 ~ 200 | 1.6 ~ 6 | ||

| 1 | 12 Days | 10 | EN 1.0330 Equiv. (EN 1.0320 Equiv. (hot-rolled)) | Trivalent Chromate (Black) | 20 ~ 200 | 10 ~ 200 | 1.6 ~ 6 | ||

| 1 | 12 Days | 10 | EN 1.0330 Equiv. (EN 1.0320 Equiv. (hot-rolled)) | Trivalent Chromate (White) | 20 ~ 200 | 10 ~ 200 | 1.6 ~ 6 | ||

| 1 | 7 Days | 10 | EN 1.4301 Equiv. (2B) | Not Provided | 20 ~ 200 | 10 ~ 200 | 1.5 ~ 4 |

Loading...

Basic information

| Type | SWBCS |

|---|

Configure

Basic Attributes

-

Material

- EN AW-5052 Equiv.

- EN 1.0330 Equiv. (EN 1.0320 Equiv. (hot-rolled))

- EN 1.4301 Equiv. (2B)

-

Surface Treatment

- Black Anodize

- Black Oxide

- Clear Anodize

- Not Provided

- Trivalent Chromate (Black)

- Trivalent Chromate (White)

-

A(mm)

-

B(mm)

-

T(mm)

-

Type

- SWBCS-AM

- SWBCS-AMB

- SWBCS-AMW

- SWBCS-SP

- SWBCS-SPB

- SWBCS-SPK

- SWBCS-SPU

- SWBCS-SUD

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 7 Days or Less

- 8 Days or Less

- 12 Days or Less

- 13 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry