ASAHI SEIKO Other Shapes(Bearing Inner Dia. Shape:Cylindrical Hole, Eccentric Collar)

| Shipping Days |

|

|---|

?* Information on days to ship and prices

-

Pillow Shape with Eccentric Wheel Method, Stainless Steel and Silver Environmentally Friendly Series, MUSP Shape

ASAHI SEIKO

The bearing, fixed eccentric wheel, and bearing box are all made of corrosion-resistant stainless steel, making the product suitable for use with machinery that doesn't handle rust well. Environmentally friendly series

[Features]

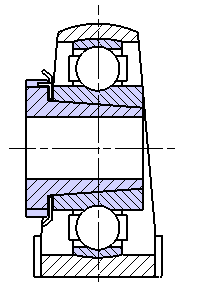

· Logical steel center: The outer wheel's outer diameter is machined into a ball surface, fitting around the center of a bearing box machined in the same way. Because both of the spherical surfaces can be aligned, this ensures logical operation of the machinery and stops erratic shaft center behavior, preventing excessive force from being applied to the bearing due to complications.

· Supply method: Simply supply fresh grease at arbitrary intervals and ensure that the bearing internal workings are ejecting old grease to the exterior as much as possible to extend working life for both grease supplies and the bearing. The cast iron series comes standard with a supply method to ensure that it can be used in severe conditions for long periods of time with complete confidence.

· Excellent sealing equipment: The bearing is double-sealed with a steel plate slinger and a heat-resistant synthetic rubber seal. Friction is low and even if the shaft tilts the seal contact is unchanged. The result is an extremely effective seal that prevents both grease leaks and contamination of the interior by external trash and moisture. Can be used with confidence even extremely poor conditions.

· This insert bearing unit with a cover can be used with confidence in poor environmental conditions such as factories engaged in steel manufacturing, milling, cement making, and casting, and in machinery for aircraft, air conditioning, and public works. The advance receiving box for units with set screws and adapters included has a steel plate or cast iron cover mounted for dust prevention, and both the bearing and the bearing box are processed with sealing equipment to improve dust-proof properties.

· Deep groove shaped internal structure: The bearing interior is identical to the deep groove ball bearing structure of the 6200 and 6300 shape. For this reason, it can support both radial and axial loads and is low noise.

· Bearing and bearing box compatibility: Because the bearing and bearing box have mutual compatibility, the bearing can be replaced on its own as necessary, which is extremely convenient.

· Easy handling: The insert bearing unit is an integrated combination of a bearing and bearing box. The bearing is preloaded with an appropriate amount of high quality lubricant grease, so it can be operating immediately as is after mounting. For this reason, there is no concern of contaminants and other materials entering the bearing during handling, preventing trouble during mounting before it occurs.

· Simple mounting to the shaft: The insert bearing unit can be mounted to the shaft on the side of the inner ring with the two included hex socket head set screws, to the inner ring using the included mounting adapter for the tapered hole in the inner diameter, or mounted with the included eccentric wheel. All of these methods are simple procedures, and the shaft machining is easy.Starting from∗ : 66.59 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

Diamond Flange Shape with Eccentric Wheel Method, Stainless Steel and Silver Environmentally Friendly Series

ASAHI SEIKO

[Features]

· The bearing, fixed eccentric wheel, and bearing box are all made of corrosion-resistant stainless steel, making the product suitable for use with machinery that doesn't handle rust well.Starting from∗ : 57.25 € Min. Shipping Days : 5 Days *Unit price with basic configuration

| Brand |

|---|

| Product Series |

| Starting from∗ |

| Min. Shipping Days : |

| Unit, Type |

| Bearing Unit, Type |

| Shaft Bore Dia. d(mm) |

| Unit Body Material |

| Bearing Inner Dia. Shape |

| Pillow Type, Category |

| Rolling Element Material |

| Surface Treatment |

| Brand | ASAHI SEIKO | ASAHI SEIKO |

|---|---|---|

| Product Series | ||

| Starting from∗ | 66.59 € *Unit price with basic configuration | 57.25 € *Unit price with basic configuration |

| Min. Shipping Days : | 5 Days | 5 Days |

| Unit, Type | Bearing Unit | Bearing Unit |

| Bearing Unit, Type | Pillow Type | Diamond-Shaped Flange Type |

| Shaft Bore Dia. d(mm) | 12 ~ 25 | 10 ~ 25 |

| Unit Body Material | - | - |

| Bearing Inner Dia. Shape | Cylindrical Hole, Eccentric Collar | Cylindrical Hole, Eccentric Collar |

| Pillow Type, Category | Standard | Standard |

| Rolling Element Material | - | - |

| Surface Treatment | - | - |

Loading...

Filter by:

Narrow search by specifying spec./dim.

-

Unit, Type

-

Bearing Unit

Bearing Unit -

Framed Bearing Unit

Framed Bearing Unit -

Others

Others

-

-

Bearing Unit, Type

-

Pillow Type

Pillow Type -

Round Flange Type

Round Flange Type -

Diamond-Shaped Flange Type

Diamond-Shaped Flange Type -

Take-Up Type

Take-Up Type -

Deformed Diamond-Shaped Flange Type

Deformed Diamond-Shaped Flange Type -

Others

Others

-

-

Shaft Bore Dia. d(mm)

-

Unit Body Material

- Cast Iron

- Stainless Steel

- Steel Plate

- Structural Steel

- Steel

-

Bearing Inner Dia. Shape

-

Pillow Type, Category

-

Rolling Element Material

-

Surface Treatment

Narrow search by specifying Brand

-

- MISUMI (0)

- ASAHI SEIKO (2)

- KMT BEARINGS (1)

- NTN (1)

- NORELEM (0)

- SKF (0)

- NIPPON PILLOW BLOCK (0)

- SANWA CONVEYOR (0)

- FAG (0)

- SNR (0)

- INA (0)

- ZEN (0)

Narrow search by specifying CAD data type

-

- 2D

- 3D