- Outer Diameter (D)(φ)

- 2

- 2.5

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 16

- 17

- 18

- 20

- Flute Length (ℓ)(mm)

- 3.5

- 4.5

- 5

- 6

- 8

- 9

- 12

- 13

- 15

- 18

- 20

- 24

- 25

- 27

- 30

- Shank Diameter (d)(mm)

- 6

- 8

- 10

- 12

- 16

- 20

- Overall Length (L)(mm)

- 80

- 100

- 120

- 135

- 150

- 160

- 180

- 200

- Length Under Neck (ℓ1)(mm)

- 30

- 35

- 50

- 70

- 85

- 100

- 108

- 120

- 140

- Type

- Becsült szállítási napok

- Minden

- 5 munkanapok belül

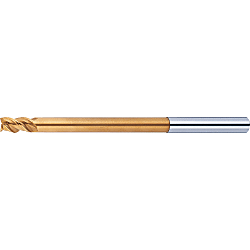

TSC series carbide multi-functional square end mill, 3-flute, 45° spiral / long shank, short model

Cikkszám:

javaslat található.Vázlatrajz

Cikkszámlista

| Cikkszám |

|---|

Egységár (HÉA nélkül)(egységár adóval) | Normál feladási dátum |

|---|

96.26 € ( 114.55 € ) | 5 munkanapok |

89.19 € ( 106.14 € ) | 5 munkanapok |

77.95 € ( 92.76 € ) | 5 munkanapok |

82.80 € ( 98.53 € ) | 5 munkanapok |

90.92 € ( 108.19 € ) | 5 munkanapok |

94.29 € ( 112.21 € ) | 5 munkanapok |

115.67 € ( 137.65 € ) | 5 munkanapok |

126.14 € ( 150.11 € ) | 5 munkanapok |

134.46 € ( 160.01 € ) | 5 munkanapok |

91.12 € ( 108.43 € ) | 5 munkanapok |

145.22 € ( 172.81 € ) | 5 munkanapok |

100.24 € ( 119.29 € ) | 5 munkanapok |

168.95 € ( 201.05 € ) | 5 munkanapok |

112.90 € ( 134.35 € ) | 5 munkanapok |

124.26 € ( 147.87 € ) | 5 munkanapok |

118.23 € ( 140.69 € ) | 5 munkanapok |

182.80 € ( 217.53 € ) | 5 munkanapok |

186.30 € ( 221.70 € ) | 5 munkanapok |

328.66 € ( 391.11 € ) | 5 munkanapok |

374.67 € ( 445.86 € ) | 5 munkanapok |

Részletes információk

Alapvető információk

[Features]

-High performance in machining general steel, EN 1.4301 Equiv. (sintered) and heat-treated steel (up to 50 HRC)

-The unique shape of the chip groove enables cutting grooves with a depth of cut equivalent to that of a two flute tool

-The application of a rounded cutting edge at the rear end of the flute suppresses machining streaks that occur when machining the side face in multiple steps (product shown in Fig. 3 only).

-The helix angle of 45° makes it ideal for high-speed machining, compared with the general helix angle of 30°

-It has a coating with high oxidation resistance and high hardness, and achieves long service life. Effective in high-speed machining and dry machining as coating properties

-Can be reground. Please refer to the "Regrinding Service" page for application procedures, range of services, prices, etc.

Specifikációk és ár

Specifications

| Model Number | Shank Diameter d |

Flute Length ℓ |

Under Neck Diameter d1 |

Length Under Neck ℓ1 |

Overall Length L |

Figure | ||

| Outer Diameter D |

Shank Diameter d |

|||||||

| TSC-LS-HEM3S | 2 | — | 6 | 3.5 | 1.9 | 30 | 80 | 1 |

| 2.5 | — | 6 | 4.5 | 2.4 | 30 | 80 | 1 | |

| 3 | — | 6 | 5 | 2.9 | 30 | 80 | 1 | |

| 4 | — | 6 | 6 | 3.8 | 35 | 80 | 1 | |

| 5 | — | 6 | 8 | 4.8 | 50 | 100 | 1 | |

| 6 | — | 6 | 9 | 5.7 | 70 | 120 | 2 | |

| 7 | — | 6 | 12 | — | — | 135 | 3 | |

| 8 | 6 | 6 | 12 | — | — | 135 | 3 | |

| 8 | — | 8 | 12 | 7.6 | 85 | 135 | 2 | |

| 9 | — | 8 | 13 | — | — | 135 | 3 | |

| 10 | 8 | 8 | 15 | — | — | 150 | 3 | |

| 10 | — | 10 | 15 | 9.5 | 100 | 150 | 2 | |

| 11 | — | 10 | 18 | — | — | 160 | 3 | |

| 12 | 10 | 10 | 18 | — | — | 160 | 3 | |

| 12 | — | 12 | 18 | 11.5 | 108 | 160 | 2 | |

| 13 | — | 12 | 20 | — | — | 160 | 3 | |

| 16 | — | 16 | 24 | 15.5 | 120 | 180 | 2 | |

| 17 | — | 16 | 25 | — | — | 180 | 3 | |

| 18 | — | 16 | 27 | — | — | 180 | 3 | |

| 20 | — | 20 | 30 | 19.5 | 140 | 200 | 2 |

[ ! ] For shank diameter (d) specifications listed in blue, specify both a outer diameter (D) and shank diameter (d).

For Cutting Conditions, Refer to >>Click here.

Jellemzők és használati példák

More Information

● It has a TS film coating with much greater oxidation resistance and hardness than conventional films, resulting in a longer operational life and ideal for high speed machining / dry machining.

● The unique tip pocket shape allows for the cutting of grooves to be achieved with 2 flutes in parallel at the cutting depth.

● The rounded edge of the blade rear end suppresses machining streaks caused by multi-stage machining of side surfaces (product in figure 3 only).