Fixing screws / round head R / fine thread

- Promotional pricing

- Volume Discount

- Order quantities extended (D-JIT)

- Stock

(i)Remark

- Please check the content on our website as the PDF does not contain the most up-to-date information.

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- More Information

- Catalog

Included Nut

Locating Screws | Screw Tip R Type | [ M ] Material | [H]Hardness * | [ S ] Surface treatment | [A]Accessory (Nut 1 pc.) | |

| [ M ] Material | [ S ] Surface treatment | |||||

| Fine | STCA | EN 1.1191 Equiv. | 45HRC or more | Black Oxide | EN 1.0038 Equiv. | Bright Chromate Plating |

| STCAM | Electroless Nickel Plating | Trivalent Chromate | ||||

| SSTCA | EN 1.4037 Equiv. | 40 to 45HRC | — | EN 1.4301 Equiv. | — | |

| Coarse | STBA | EN 1.1191 Equiv. | 40 to 45HRC | Black Oxide | EN 1.0038 Equiv. | Bright Chromate Plating |

| STBAM | Electroless Nickel Plating | Trivalent Chromate | ||||

| STBAS | EN 1.4301 Equiv. | — | — | EN 1.4037 Equiv. | — | |

| SSTBA | EN 1.4037 Equiv. | 40 to 45HRC | — | |||

[!] Stainless steel hardened type (EN 1.4037 Equiv.) may have individual differences in color due to hardening. (Image: Right)

[ ! ] Shipped with the included nut already attached to main body.

* [H]Hardness: Hardened Tip

Specification Table

| Part Number | — | L |

| STBA10 | — | 50 |

| M | T (Coarse) | T1 (Fine) |

| 4 | 3.2 | 4 |

| 5 | 4 | |

| 6 | 5 | |

| 8 | 6.5 | 5 |

| 10 | 8 | 6 |

| 12 | 10 | |

| 16 | 13 | 8 |

| M | M × Pitch | B | (C) | H | (ℓ1) | (r) | Z | d | SR1 | |

| Fine | Coarse | |||||||||

| 4 | 4 × 0.5 | 4 × 0.7 | 7 | 8.1 | 2.8 | 2.1 | 0.2 | 3 | 2 | 3 |

| 5 | 5 × 0.5 | 5 × 0.8 | 8 | 9.2 | 3.5 | 2.4 | 3 | 4 | ||

| 6 | 6 × 0.75 | 6 × 1.0 | 10 | 11.5 | 4 | 3.0 | 0.3 | 3.5 | 4.5 | |

| 8 | 8 × 0.75 | 8 × 1.25 | 13 | 15.0 | 5.5 | 3.7 | 0.4 | 5 | 6 | 5 |

| 10 | 10 × 1.0 | 10 × 1.5 | 17 | 19.6 | 7 | 4.5 | 0.5 | 5.5 | 7 | |

| 12 | 12 × 1.0 | 12 × 1.75 | 19 | 21.9 | 8 | 5.2 | 7 | 9 | 8 | |

| 16 | 16 × 1.5 | 16 × 2.0 | 24 | 27.7 | 10 | 6 | 0.6 | 9 | 12 | 10 |

| Part Number | L Selection | ||||||||||||||||||

| Type | M | STCA·STBA | STCAM·SSTCA·STBAM STBAS·SSTBA | ||||||||||||||||

| (Fine) STCA STCAM SSTCA (Coarse) STBA STBAM STBAS SSTBA | 4 | 15 | 20 | 25 | 30 | 35 | 40 | 20 | |||||||||||

| 5 | 15 | 20 | 25 | 30 | 35 | 40 | 50 | 20 | |||||||||||

| 6 | 15 | 20 | 25 | 30 | 35 | 40 | 50 | 20 | 25 | 30 | 40 | 50 | |||||||

| 8 | 15 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 70 | 80 | 25 | 30 | 40 | 50 | 60 | ||||

| 10 | 30 | 35 | 40 | 50 | 60 | 70 | 80 | 30 | 40 | 50 | 60 | 70 | |||||||

| 12 | 30 | 35 | 40 | 50 | 60 | 70 | 80 | 40 | 50 | 60 | 70 | 80 | |||||||

| 16 | 50 | 60 | 70 | 80 | — | ||||||||||||||

| Mass (g) Ref. Value | |||

| M dimension | L | Steel product | Stainless steel product |

| 4 | 15 | 2.10 | 2.12 |

| 20 | 3.20 | 3.23 | |

| 25 | 4.30 | 4.34 | |

| 30 | 5.40 | 5.46 | |

| 35 | 6.80 | 6.87 | |

| 40 | 7.40 | 7.48 | |

| 5 | 15 | 3.70 | 3.74 |

| 20 | 4.90 | 4.95 | |

| 25 | 6.20 | 6.26 | |

| 30 | 7.50 | 7.58 | |

| 35 | 8.30 | 8.38 | |

| 40 | 9.60 | 9.70 | |

| 50 | 11.10 | 11.21 | |

| 6 | 15 | 6.20 | 6.26 |

| 20 | 7.80 | 7.88 | |

| 25 | 8.80 | 8.89 | |

| 30 | 9.80 | 9.90 | |

| 35 | 11.80 | 11.92 | |

| 40 | 13.80 | 13.94 | |

| 50 | 15.80 | 15.96 | |

| 8 | 15 | 12.40 | 12.53 |

| 20 | 14.80 | 14.95 | |

| 25 | 17.60 | 17.78 | |

| 30 | 19.30 | 19.50 | |

| 35 | 21.10 | 21.32 | |

| 40 | 22.70 | 22.93 | |

| 50 | 26.10 | 26.37 | |

| 60 | 29.50 | 29.80 | |

| 70 | 31.30 | 31.62 | |

| 80 | 34.20 | 34.55 | |

| 10 | 30 | 35.80 | 36.16 |

| 35 | 41.50 | 41.92 | |

| 40 | 47.20 | 47.68 | |

| 50 | 52.90 | 53.44 | |

| 60 | 58.60 | 59.20 | |

| 70 | 60.50 | 61.12 | |

| 80 | 64.30 | 64.96 | |

| 12 | 30 | 46.70 | 47.18 |

| 35 | 51.60 | 52.13 | |

| 40 | 58.20 | 58.79 | |

| 50 | 64.90 | 65.56 | |

| 60 | 71.60 | 72.33 | |

| 70 | 78.30 | 79.10 | |

| 80 | 85.00 | 85.87 | |

16 | 50 | 89.30 | 90.21 |

| 60 | 96.60 | 97.58 | |

| 70 | 103.20 | 104.25 | |

| 80 | 115.60 | 116.78 | |

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | RoHS | Material | Thread Type | Thread Dia. M | Thread Pitch | Screw Length L | Surface Treatment | |

|---|---|---|---|---|---|---|---|---|---|---|---|

5.44 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 4 | 0.7 | 20 | - | |

5.44 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 5 | 0.8 | 20 | - | |

5.69 € 2.05 € | 1 | Available |

Same day

Stock | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 6 | 1 | 20 | - | |

5.69 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 6 | 1 | 25 | - | |

5.69 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 6 | 1 | 30 | - | |

5.69 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 6 | 1 | 40 | - | |

5.69 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 6 | 1 | 50 | - | |

6.58 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 8 | 1.25 | 25 | - | |

6.58 € | 1 | Available |

Same day

Stock | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 8 | 1.25 | 30 | - | |

6.58 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 8 | 1.25 | 40 | - | |

6.58 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 8 | 1.25 | 50 | - | |

6.58 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 8 | 1.25 | 60 | - | |

8.22 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 10 | 1.5 | 30 | - | |

8.22 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 10 | 1.5 | 40 | - | |

8.22 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 10 | 1.5 | 50 | - | |

8.22 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 10 | 1.5 | 60 | - | |

8.22 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 10 | 1.5 | 70 | - | |

10.75 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 12 | 1.75 | 40 | - | |

10.75 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 12 | 1.75 | 50 | - | |

10.75 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 12 | 1.75 | 60 | - | |

10.75 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 12 | 1.75 | 70 | - | |

10.75 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Coarse | 12 | 1.75 | 80 | - | |

5.44 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 4 | 0.5 | 20 | - | |

5.44 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 5 | 0.5 | 20 | - | |

5.69 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 6 | 0.75 | 20 | - | |

5.69 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 6 | 0.75 | 25 | - | |

5.69 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 6 | 0.75 | 30 | - | |

5.69 € 3.02 € | 1 | Available |

Same day

Stock | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 6 | 0.75 | 40 | - | |

5.69 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 6 | 0.75 | 50 | - | |

6.58 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 8 | 0.75 | 25 | - | |

6.58 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 8 | 0.75 | 30 | - | |

6.58 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 8 | 0.75 | 40 | - | |

6.58 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 8 | 0.75 | 50 | - | |

6.58 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 8 | 0.75 | 60 | - | |

8.22 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 10 | 1 | 30 | - | |

8.22 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 10 | 1 | 40 | - | |

8.22 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 10 | 1 | 50 | - | |

8.22 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 10 | 1 | 60 | - | |

8.22 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 10 | 1 | 70 | - | |

10.75 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 12 | 1 | 40 | - | |

10.75 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 12 | 1 | 50 | - | |

10.75 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 12 | 1 | 60 | - | |

10.75 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 12 | 1 | 70 | - | |

10.75 € | 1 | Available | 5 Days | 10 | [Stainless Steel] EN 1.4037 Equiv. | Fine | 12 | 1 | 80 | - | |

2.27 € | 1 | Available | 5 Days | 10 | [Steel] EN 1.1191 Equiv. | Coarse | 4 | 0.7 | 15 | Black Oxide | |

2.27 € | 1 | Available | 5 Days | 10 | [Steel] EN 1.1191 Equiv. | Coarse | 4 | 0.7 | 20 | Black Oxide | |

2.27 € | 1 | Available | 5 Days | 10 | [Steel] EN 1.1191 Equiv. | Coarse | 4 | 0.7 | 25 | Black Oxide | |

2.96 € | 1 | Available | 5 Days | 10 | [Steel] EN 1.1191 Equiv. | Coarse | 4 | 0.7 | 30 | Black Oxide | |

2.27 € 1.04 € | 1 | Available |

Same day

Stock | 10 | [Steel] EN 1.1191 Equiv. | Coarse | 4 | 0.7 | 35 | Black Oxide | |

2.27 € 1.18 € | 1 | Available |

Same day

Stock | 10 | [Steel] EN 1.1191 Equiv. | Coarse | 4 | 0.7 | 40 | Black Oxide | |

2.27 € | 1 | Available | 5 Days | 10 | [Steel] EN 1.1191 Equiv. | Coarse | 5 | 0.8 | 15 | Black Oxide | |

2.27 € | 1 | Available | 5 Days | 10 | [Steel] EN 1.1191 Equiv. | Coarse | 5 | 0.8 | 20 | Black Oxide | |

2.27 € | 1 | Available |

Same day

Stock | 10 | [Steel] EN 1.1191 Equiv. | Coarse | 5 | 0.8 | 25 | Black Oxide | |

2.27 € | 1 | Available |

Same day

Stock | 10 | [Steel] EN 1.1191 Equiv. | Coarse | 5 | 0.8 | 30 | Black Oxide | |

2.27 € | 1 | Available |

Same day

Stock | 10 | [Steel] EN 1.1191 Equiv. | Coarse | 5 | 0.8 | 35 | Black Oxide | |

2.27 € | 1 | Available | 5 Days | 10 | [Steel] EN 1.1191 Equiv. | Coarse | 5 | 0.8 | 40 | Black Oxide | |

2.27 € | 1 | Available | 5 Days | 10 | [Steel] EN 1.1191 Equiv. | Coarse | 5 | 0.8 | 50 | Black Oxide | |

2.40 € | 1 | Available | 5 Days | 10 | [Steel] EN 1.1191 Equiv. | Coarse | 6 | 1 | 15 | Black Oxide | |

2.40 € | 1 | Available |

Same day

Stock | 10 | [Steel] EN 1.1191 Equiv. | Coarse | 6 | 1 | 20 | Black Oxide | |

4.06 € | 1 | Available | 5 Days | 10 | [Steel] EN 1.1191 Equiv. | Coarse | 6 | 1 | 25 | Black Oxide |

Loading...

General Information - Set Screws With Stopper

Selection details of adjusting screws/locating bolts

- Material: steel, stainless steel

- Coatings: uncoated, burnished, chromated, nickel-plated, galvanised

- Hardness: 40 to 50HRC

- Thread: standard thread, fine thread

- External thread: M3 to M20

- Drive: hexagon socket, external hexagon, spanner flat, knurled head

- Length: 10 to 120 mm

Description/Basics

Adjusting screws for mechanical engineering are intended primarily for positioning the most diverse components. In this case, the adjustment screw sets a predetermined distance of the respective component.

Depending on the application, the MISUMI range offers adjusting screws with control threads and adjusting screws with fine threads. A fine-threading facilitates positioning, since a smaller torque is required for the adjustment. Due to the lower slope of the fine thread, a fine threaded adjusting screw is loosened with less probability than one with standard threads. Another advantage of fine threading is the higher load capacity, which allows higher loads to be accommodated in axial direction. In addition, a locating bolt with a fine thread can generate a higher actuating force due to the low pitch.

The loosening or unintentional adjustment of an adjusting screw can be prevented with a locknut. Depending on the design, the appropriate nut is supplied as an accessory for the adjusting screw. Please see the specifications for more information.

An adjusting screw with knurled head facilitates easy manual adjustment without additional tools. The adjusting screw with knurled head is often used where regular adjustment or component replacement is necessary.

The locating bolt is available with a hardened contact surface. It may be hardened on the thread face or on the head or drive. Tempering ensures greater wear protection of the adjusting screw and increases the service life compared to conventional adjusting screws. The additional compensation process can cause discoloration of the material near the contact surface.

Adjusting screws are also available in the form of hexagon sockets. Without a head as drive, which can be advantageous, especially in inaccessible places.

Adjusting screws are often used in combination with stop pins or height adjusting pins. These bolts are inserted into the component to be moved in order to protect it from wear and tear or damage due to multiple adjustments.

Adjusting screws are often found in workpiece carriers and clamping devices. MISUMI also offers similar adjusting screws or locking bolts with a brush head in the form of stopper bolts.

MISUMI offers suitable threaded stopper blocks, optionally with standard threads and fine threads.

Application Examples - Set Screws With Stopper

Application example - adjusting screw set screw

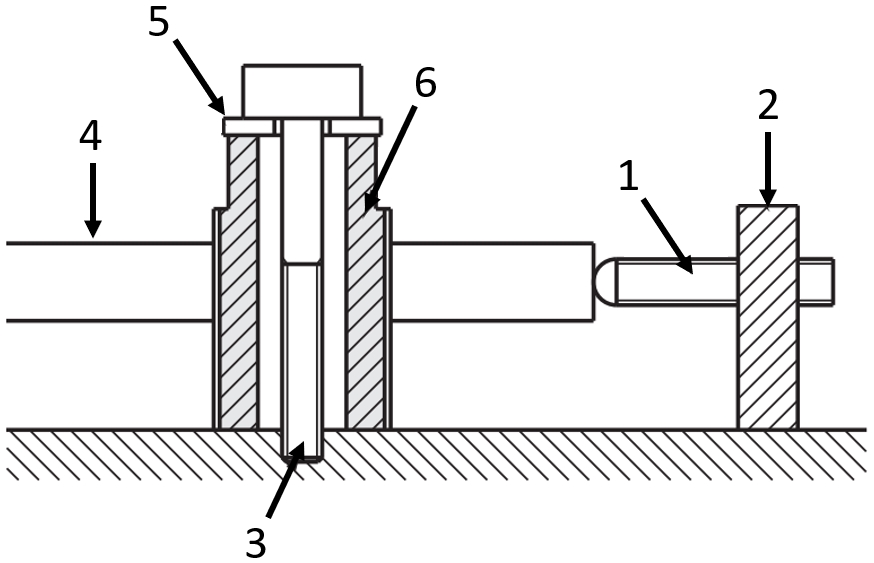

(1) Adjusting screw, (2) threaded stopper block, (3) screw, (4) base plate (meviy ), (5) washer, (6) levelling element

Application example - adjusting screw with nut

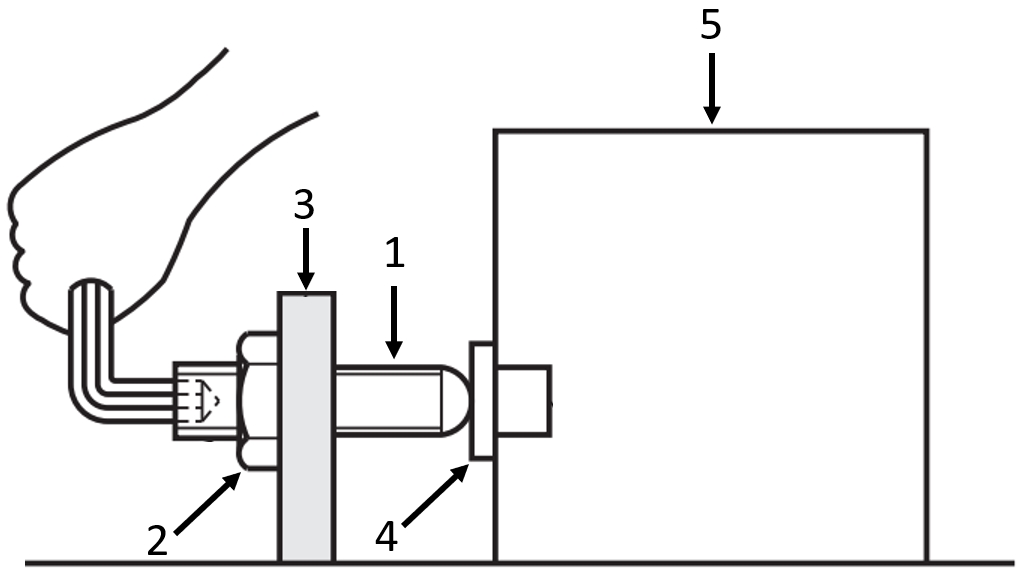

Application example – (1) adjusting screw, (2) nut , (3) threaded stopper block, (4) stop pin , (5) movable object

Industrial Applications

Basic information

| Type | Hex |

|---|

Configure

Stock

-

- Show only stock items

Basic Attributes

-

Material

- Steel

- Stainless Steel

- Steel

-

Thread Type

- Coarse

- Fine

-

Thread Dia. M

-

Thread Pitch

-

Screw Length L

-

Surface Treatment

- Black Oxide

- Electroless Nickel Plating

-

Type

- SSTBA

- SSTCA

- STBA

- STBAM

- STBAS

- STCA

- STCAM

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- Same day

- 5 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently Asked Questions (FAQ)

-

Question:

How can an adjusting screw be secured?

-

Answer:

An adjusting screw should not be secured with screw locking means as with standard screws. Adjusting screws should remain movable so that it can ensure a set distance. The countering of an adjusting screw with a nut is usually sufficient. Therefore, a position can be defined and simply changed by loosening the lock nut.

-

Question:

Is there a more precise positioning than that of an adjusting screw?

-

Answer:

For precise positioning, MISUMI offers adjusting screws with fine threads. Due to the lower slope, these enable more precise positioning or adjustment. Alternatively, a micrometre screw can also be used for low adjustment forces. Similar to stages (coordinate tables), micrometre screws enable highly accurate positioning.

-

Question:

Do you have adjustment screws without head?

-

Answer:

MISUMI offers adjusting screws as set screw without head. These are usually provided with an hexagon socket as a drive for fastening or loosening. The adjusting slide as a threaded pin is also significantly more wear-resistant with the hardened tip than conventional set screws.

-

Question:

Why is the adjusting screw only coated on one side?

-

Answer:

If an adjusting screw has a unilateral colouration, it is not necessarily the coating. The discoloration is caused by heat treatment, which is also known as an initial colour and does not result in any disadvantages. This tempering process ensures a higher hardness of the material in order to counteract occurring wear.

-

Question:

For what do you use an adjusting screw?

-

Answer:

The purpose of using an adjusting screw is multiple. Adjusting screws or locating bolts are used in the industry primarily for the positioning of various components. They set and maintain a predetermined distance from an object. Adjusting screws are often used in coordinate tables in order to adjust the table. From time to time, adjustment screws are also used in mechanical engineering, e.g., for stroke limitation of the industrial shock absorbers.

Complementary Products

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry

![[Precision] X-Axis / Cross Roller](http://content.misumi-ec.com/image/upload/f_auto,t_product_recommend_a/v1/p/jp/product/series/110300196460/110300196460_001.jpg)